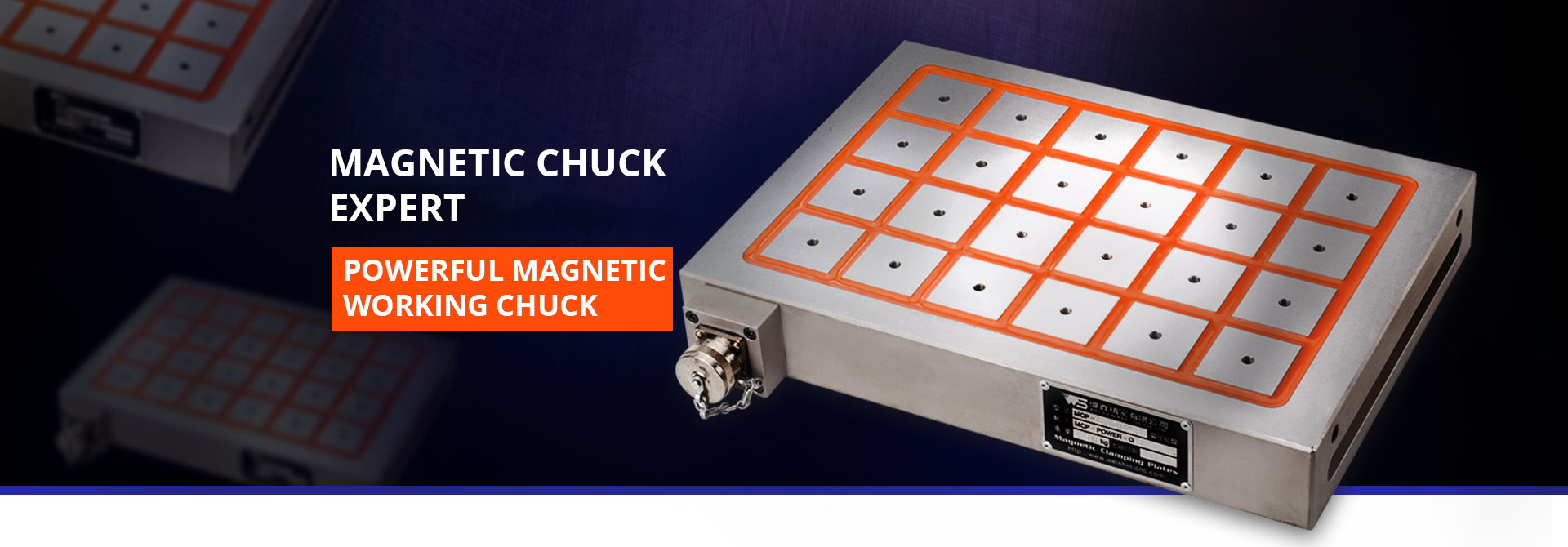

Electro-Permanent Magnetic Chuck/ Magnetic Working Chuck

MCP-Permanent Electro Magnetic Chuck

The magnetic chuck of MCP series have specially designed magnetic circuit. They are designed with special magnetic circuits without the need for continuous power supply and with strong suction and no demagnetization. They can be customized according to different needs of customers, and they can overcome general processing restrictions imposed by traditional clamping patterns, to facilitate cutting and processing of workpieces of irregular shapes or of those hard to be clamped.

The controllers can be adjusted by way of different shifts, and can cope with processing of thick and thin pieces. The hole piercing and five-sided processing can be conducted based on different situations upon the choice of induction block. This fast clamping system can save 50% less time than traditional ones , thereby enhancing the efficiency and competitiveness of the enterprise; the immediate results can be seen right after application.

Special Anti-rust Treatment

The magnetic chuck have special internal magnetic circuit designs; they are stable and won't be demagnetized; they have waterproof connectors, and the magnetic chuck surface is designed with special anti-rust treatment.

Application

The magnetic chuck take advantages of five-sided processing, heavy cutting processing, high-speed precision processing, mold parts processing, grinding processing etc.

Powerful magnetic force up to 1300kg / 100cm² (4-poles ).

Electricity-saving; electricity needed only for magnetization and demagnetization.

Quickly load and unload workpiece, more fixed than clamp plate saving 50% of time.

Stable and excellent Magnetic Chuck, it could be used for long time and never get hight temperatures to affect the accuracy of workpieces.

Customization of magnetic chuck is acceptable.